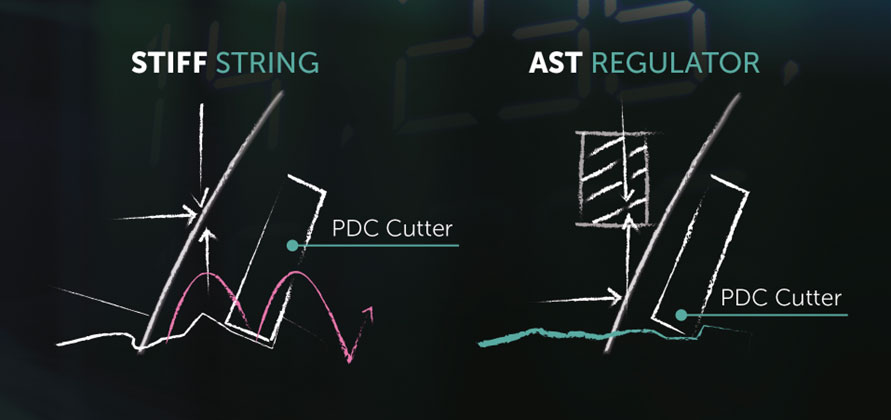

Function:

The Tomax Anti Stick-slip Tool (AST) stabilizes drilling torque originating from the bit through a direct mechanical process where excess torque causes the tool to contract along internal helical splines. This contraction will effectively decrease the depth-of-cut and prevent further accumulation of torque. An internal spring is energized in the process and will cause the tool to extend, thereby increasing depth-of-cut when drilling torque decreases. This process ensures continuous efficient drilling is maintained and destructive stick-slip effects are limited.

Bottomhole Assembly (BHA):

The AST tool is typically placed in the BHA directly above the non-magnetic drill collars. If a roller-reamer or a stabilizer is placed near the AST, then it is recommended to position the AST below it. DO NOT position the AST in a string transition area e.g. between drill collars and heavy weight drill pipe (HWDP). Special recommendations are:

UNDER REAMER:

In a BHA with an under-reamer, the AST must be placed above the under-reamer and should be spaced out by a collar or pony collar to limit bending forces on the AST.

STEERABLE MUD MOTOR (PDM):

In steerable PDM assemblies, the AST must be placed above the MWD as there is some torsional movement which can affect the tool-face.

PDM DRIVEN RSS ASSEMBLY:

The AST may be placed below the PDM in a motorized RSS assembly. Always consider the risk of fatigue. A flex-wate or flexible sub between the motor and the AST is recommended. See Illustration C.

HIGH CURVATURE (DLS) WELLBORES:

In applications where the doglegs exceed the specified Endurance Dogleg Limit, there MUST be flexible joints (Illustration C) above and below the AST. The purpose is to increase the fatigue-life of the tool.

Below are limits from the Product Fact Sheet for the most relevant tools. More specific information is found in the Operational Limits section.

| TOOL | ENDURANCE DOGLEG LIMIT | NON-ROTATING DOGLEG LIMIT |

| 4.75 XC-AST | 10 deg/100ft (30m) | 13 deg/100ft (30m) |

| 5.25 XC-AST | 10 deg/100ft (30m) | 13 deg/100ft (30m) |

| 5.25 XC-AST w/flex-wates/subs | 12 deg/100ft (30m) | 15 deg/100ft (30m) |

| 6.75 XC-AST | 8 deg/100ft (30m) | 10 deg/100ft (30m) |

| 6.75 XC-AST w/flex-wates/subs | 10 deg/100ft (30m) | 13 deg/100ft (30m) |

| 7 CD-AST | 12 deg/100ft (30m) | 15 deg/100ft (30m) |

Handling:

The AST unit is robust and cannot be damaged by standard pipe-handling equipment. However, under no circumstances should any handling tools or equipment be used on the chromed surface of the telescopic extension (Illustration A).

The AST is fitted with a yellow protective transport clamp (Illustration B). Remove the clamp before picking up the tool and replace it when the tool is laid out. Do not run the clamp into the well. Do not keep the clamp on while the AST is made up in the BHA or racked in the derrick, as it could be a potential falling object hazard if it should come off the tool. Please return the tool with both thread protectors and the protective transport clamp.

CAUTION 1:

Do not torque or break any connections on the AST tool body, these are proprietary connections with specific recorded torque values.

CAUTION 2:

The tool can compress and rotate slightly if weight is applied during handling in the rotary table.

CAUTION 3:

Remove the protective clamp (Illustration B) before the AST is made up in the BHA.

Drilling:

The stroke of the tool is sufficient to provide the desired effect without special configuration. The mean WOB is controlled from the surface and no changes apply to standard drilling procedures. The value to be expected is smooth torsional response, better drill-bit efficiency and reduced vibrations. The tool comes with no specialist at the well site, so the driller must make decisions on continued use or replacement of the AST in case of a consecutive bit run. See “Surface Check” and “Lay-Out Criteria” in this manual.

Operating Limits:

Fatigue damage to BHA components will occur when it is rotated in doglegs above the Endurance Dogleg Limit (see explanation below). Applications where fatigue damage is an issue include medium-radius wells (high dogleg) and motorized BHA (high RPM). Tomax has developed a set of operating limits to prevent fatigue issues based on these terms:

ENDURANCE DOG-LEG LIMIT:

Below this limit, fatigue is not an issue. Above this limit, fatigue damage will occur, and mitigation is needed to reduce the damage; use flexible sections (Illustration C) to reduce stress. Also limit operating hours – see “Lay-out Criteria” in this manual.

NON-ROTATING DOG-LEG LIMIT:

This limit should not be exceeded. Fatigue failure may occur after a few rotations. For actual limits, see fact sheet at tomax.no/products.

SURFACE CHECK:

- Wipe the polished section of the telescoping mandrel and check for oil / mud leakage.

- Check the same, polished section for mechanical damage.

LAY-OUT CRITERIA:

- If failed above surface acceptance check or

- At maximum recommended rotating hours where AST is placed above a motor (PDM) or there is no motor in the BHA, and the doglegs are within the Endurance Dogleg Limit: The maximum recommended rotating hours as per rig/IADC report on an AST tool is 200. In practical terms, the tool should be laid out prior to a run that will result in accumulated rotating hours beyond 200.

- Applications where AST is placed below a motor (PDM): The maximum recommended rotating hours (as per IADC report) on an AST tool is 100. In practical terms, the tool should be laid out prior to a run that will result in accumulated rotating hours beyond 100.

- Applications where the doglegs have exceeded the ENDURANCE DOGLEG LIMIT: The maximum recommended rotating hours (as per IADC report) on an AST tool is 100. In practical terms, the tool should be laid out prior to a run that will result in accumulated rotating hours beyond 100.

- Applications where the doglegs have exceeding the NON-ROTATING DOG-LEG LIMIT, including doglegs measured over a distance from 15 to 50 feet, then the AST may have suffered accelerated fatigue wear and should be laid out ASAP.

- Abnormal conditions: E.g. excessive jarring, drilling with a ringed out or under gauged bit, damaged under-reamer, high sand / solids content in the mud and abnormal, then the AST may have suffered accelerated wear and should be laid out ASAP.