Products

Anti stick-

slip

tool

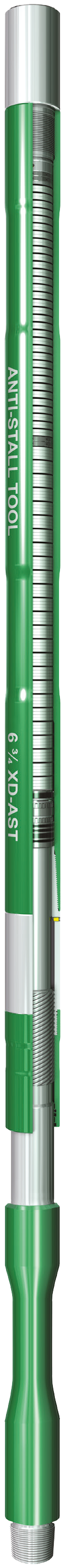

The Anti Stick-slip Tool (AST) from Tomax ensures stable loading of PDC bits in all kinds of rock. This allows the cutters to cross boundaries with minimal waste of energy and low risk from vibrations.

Autonomous regulation of the drill-bit interface has proven useful for drillers aiming for continuous improvement of operational efficiency.

The millisecond response of the AST reduces losses to friction at the rock interface. This leaves more energy available to cut rock faster and at the same time reduces cutter heat and, consequently, wear.

12,000+

Tomax has contributed to more effective drilling in more than 12,000 wells around the world.

Downhole tool sizes

Use of the AST requires no changes to standard drilling practices. The tool has a wide working range which eliminates the need for service personnel.

PLACEMENT

IN BHA

The standard placement of the AST tool is on top of the non-magnetic portion of the BHA. This is the same for rotary steerable systems, downhole motors and rotary assemblies.

BHA configuration examples for RSS/Under Reamer BHA RSS/LWD BHA and motor BHA. For hard rock and high friction formations, a roller reamer above the AST is recommended.