Use of very aggressive PDC cutters, a RSS system with a mud motor and an AST produced a steady cut through hard limestone and repeatedly drilled sections to TD in one run.

Objectives

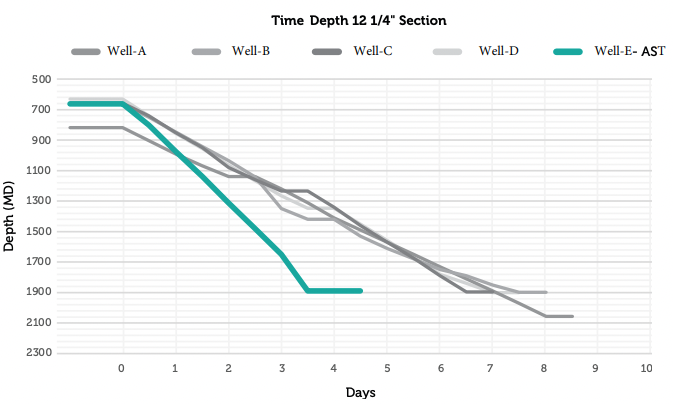

Improved drilling performance was identified as a prerequisite for revitalising the BP Ula field on the Norwegian Continental Shelf. This implied drilling a 2100m (6800’) notoriously difficult 12 ¼” hole-section spanning three geological periods with a minimum of bit runs. The Anti Stick-slip Tool technology, previously applied to solve drilling challenges in a nearby field, was picked again for this project, to cut vibration and offload the PDM motor driving the RSS and a sharp bit through formation transitions while maintaining effective penetration.

FACTS

Tool

9” HB-AST

Client

BP Norge AS

Country

Norway

Field

Ula

Rig

Ula Drilling

Section

12 ¼”

BHA

12 ¼” DBS Security bit, Baker Hughes Auto-Trak X-treme and MWD suite.

Results

On bottom, MWD data verified the absence of severe vibration giving the drilling team full freedom to optimize the drilling parameters as per program. The formations encountered shifted from soft shale and mudstone, to a massive limestone with chert nodules and challenging transitions inbetween.