New, counterforce assisted XC-AST Reveal Hard Rock Potential with PDC Bits

Objective

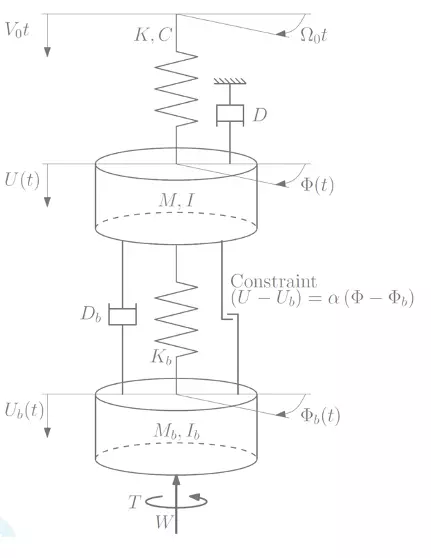

The cost of hard rock drilling grows exponentially with depth. That is not good news for geothermal projects. The exponent in the cost equation is the footage per bit. Tomax took on a full-scale test to find what could be done to PDC durability in basement rock by optimizing the balance in the rock-cutter interface.

FACTS

Tool

6 3/4” XC-AST

Country

Norway

Rig

Ullrigg

Section

8 ½”

BHA

PDC and AST

November 2015

Results

A 6 ¾” XC-AST tool was made up in the BHA with a new, API class M333 PDC bit from Halliburton DBS. On bottom, the energy to drill, or Mechanical Specific Energy (MSE), was continuously monitored to look for wear. It was evident that the bit would produce a steady cut with no axial impact loading. When speeding up by adding WOB, the MSE started indicating wear. The WOB was reduced and thanks to the self-sharpening effect of modern PDC cutters, the MSE recovered.

Value

Igneous rock generally has a high coefficient of friction. It became a valuable experience how heating and wear from friction was a big durability-barrier when the impact risk from the high compressive strength was solved.