Midland Basin (Spraberry and Wolfcamp)

Objective

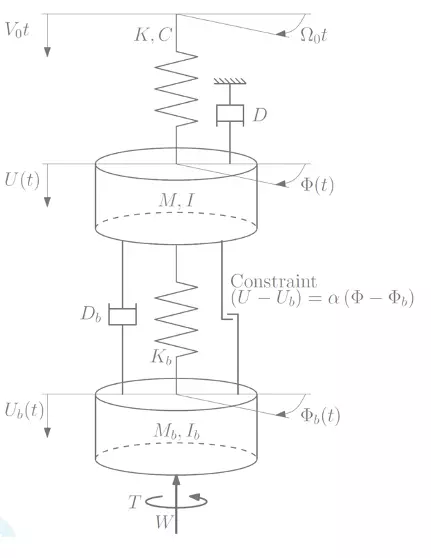

The Tomax Anti Stick-Slip Tool (AST) reduces motor wear from stalls. Stalls includes the short invisible stops from High Frequency Torsional Oscillations or HFTO. Minimized stalls keeps the motor stronger for longer. Guidon Energy implemented AST in the Midland Basin to try out the PDM preservation approach:

FACTS

Tool

6 3/4” XC-AST

Country

USA

Area

Midland Basin

Section

8 ½ and 7 7/8”

BHA

Steerable PDM

July 2019 to January 2020

Results

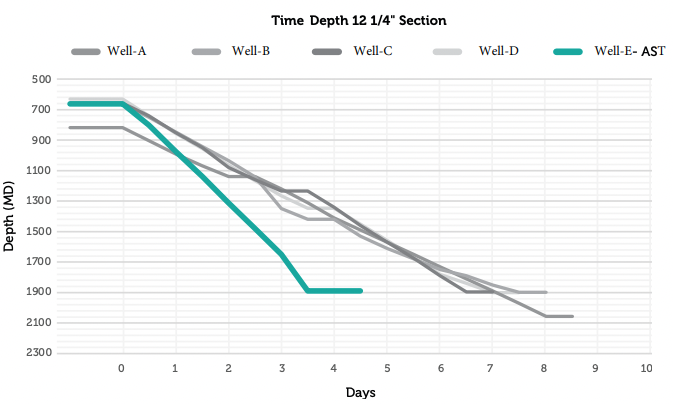

The implementation in Guidon’s Spraberry wells started in Q3 of 2019. AST was implemented on all rigs in Q4 of the same year. The daily footage improved consistently with the implementation and had improved by 40% by the end of Q4. The Wolfcamp implementation started in Q1 of 2020 and gave an improvement of 20% in the first quarter.

Value

The AST delivered direct improvements in daily footage from less failures and faster penetration.

While efficiency was increased, the MWD data showed averages for Lateral and Tangential Shocks fell 23% and 16% respectively.