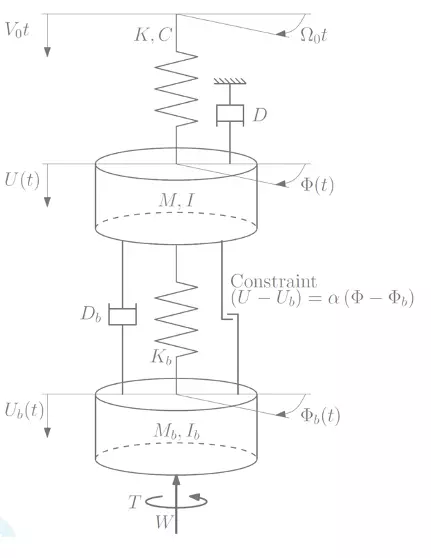

The maximum drilling torque supplied from the Top Drive is defined by the highest peaks produced downhole. An AST can be used to reduce such downhole peaks.

Objectives

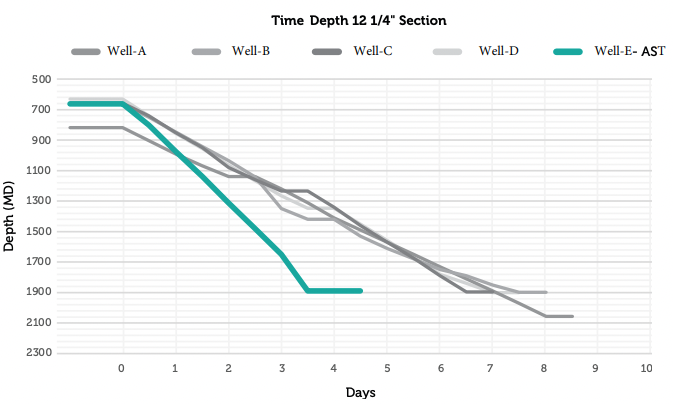

Deep wells in hard or abrasive formations can create significant rotary friction on the drill string. At the same time, these formations often demand high bit RPM to drill reasonably fast. When drilling the horizontal sections in the Alvheim field, the operator, Marathon Petroleum Norge AS, a wholly owned subsidiary of Marathon Oil Corporation (NYSE: MRO), found the Top Drive System (TDS) to be overloaded at high RPM (high-gear) and was forced to shift to low-gear at the cost of penetration rate. The operator therefore decided to run anti-stall technology to level out downhole torsional peaks originating from the bit and under-reamer to reduce the TDS load at surface.

FACTS

Tool

6 ¾” XD-AST

Client

Marathon

Country

Norway

Field

Alvheim

Rig

Deep Sea Bergen

Section

8 ½” x 9.25”

BHA

8 ½” bit (PDC) BHI AutoTrak RSS and MWD suite, 9.05” Ander-Reamer

Results

With a 6 ¾” XD-AST tool in the BHA, drilling commenced in high-gear practically all the way to TD and the TDS showed no sign of overload. The ROP consequently broke all previous records for the section.

Value

Overall penetration improvement gave a saving over comparable runs of 1 day or USD 750k, not including the reduced risk to the BHA.