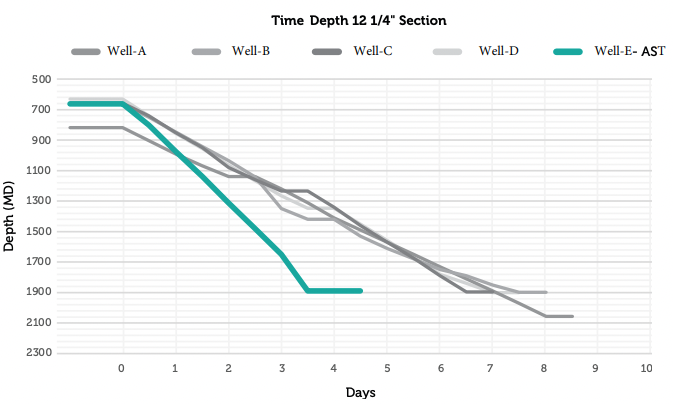

First case report with practically full AST implementation

The Aker BP drilling team had an ambitious goal for speed on Ivar Aasen. As a result, the Tomax downhole technology was brought in for qualification right from the appraisal phase.

Objectives

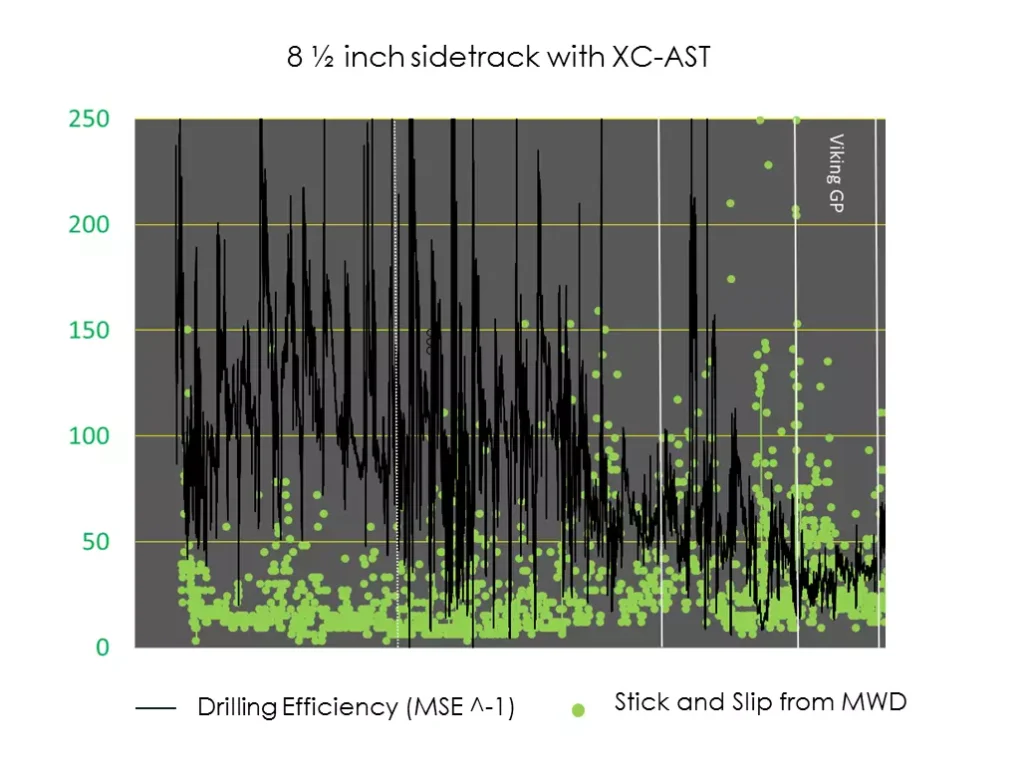

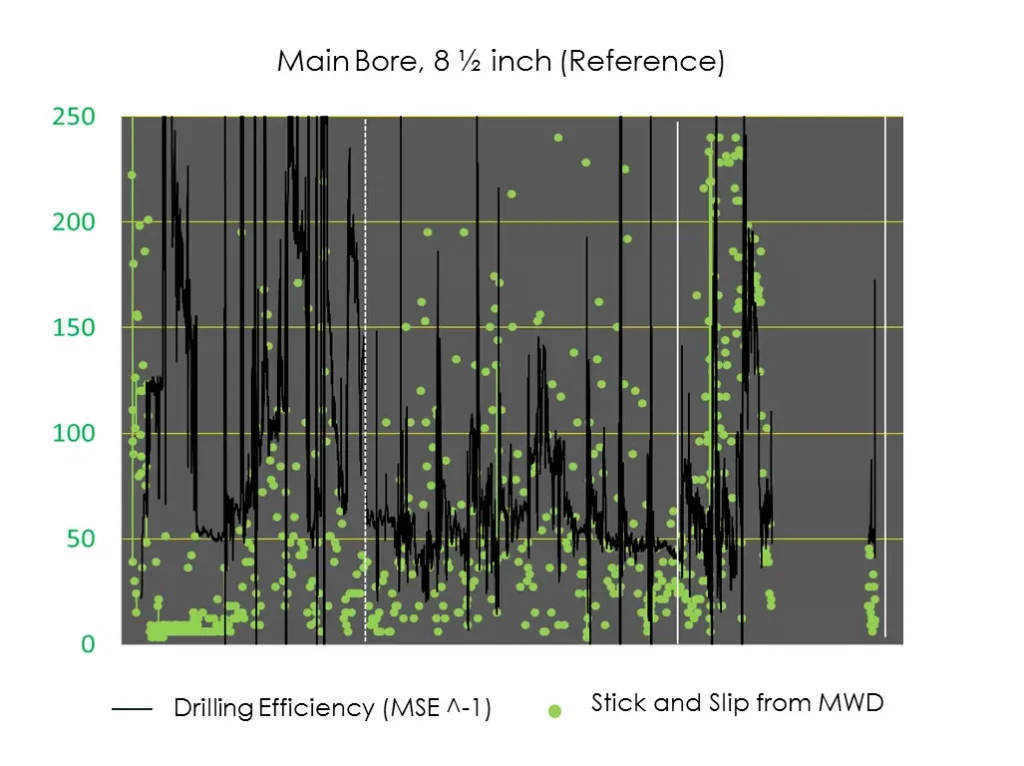

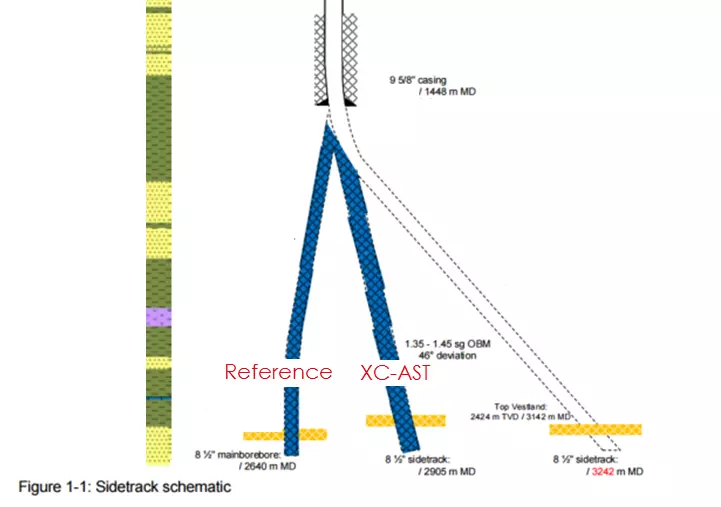

The ROP target for the campaign was as fast as 100 m/hr through the overburden. The target was set to save rig time and to minimize open-hole exposure. The latter is known to provide the best possible reliability in casing and cementing operations. The objective was to use the autonomous response of the AST tool to safeguard against vibrations when entering and departing stringers at fast speeds.

FACTS

Tool

9 ½, 8 ¼ and 6 ¾ XC-AST

Client

Aker BP

Country

Norway

Rig

Maersk Interceptor

Section

16, 12 ¼ and 8 1/2”

BHA

Schlumberger RSS

Time of report

January 2017

Results

The tool showed clear, universal advantages: faster ROP was achieved with less input energy. This meant maximized speed with low risk from vibrations. No failures were encountered with the drill-string or the borehole.

Value

In October 2016, the Norwegian Petroleum Directorate (NPD) formally acknowledged the drilling savings on Ivar Aasen. The production was approved to start on time and on budget.