Zadco UAE (Upper Zakum Development Company), with majority shareholder ADNOC, needed to expand ERD capabilities beyond 10,000m and saw excessive friction and stick-slip as challenges.

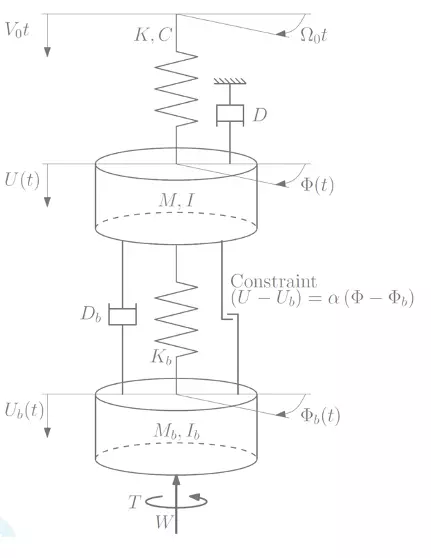

When friction induces stick-slip oscillations in log strings, the WOB transfer can stop during the stick periods. Then, when the bit eventually slips, the velocities will peak simultaneously in both axial and angular (RPM) rotational directions. The results are poor mechanical drilling efficiency, shocks and performance issues with the MWD and RSS tools, deteriorating towards TD.

FACTS

Tool

6 ¾” XC-AST

Client

Zadco (ADNOC)

Country

USA

Field

Upper Zakum

Section

8 1/2″ lateral

BHA

RSS+PDM (Schlumberger and Halliburton)

2016 and on

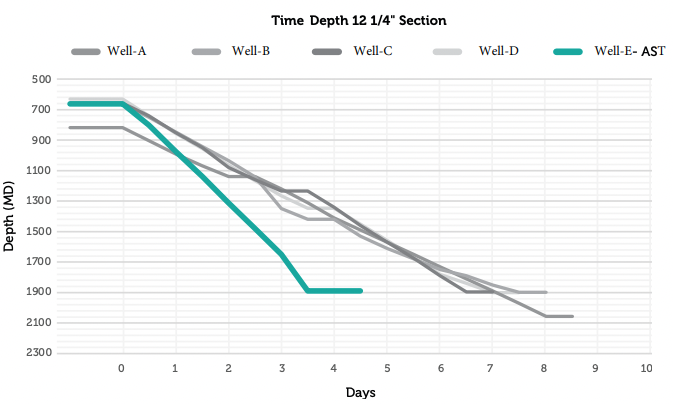

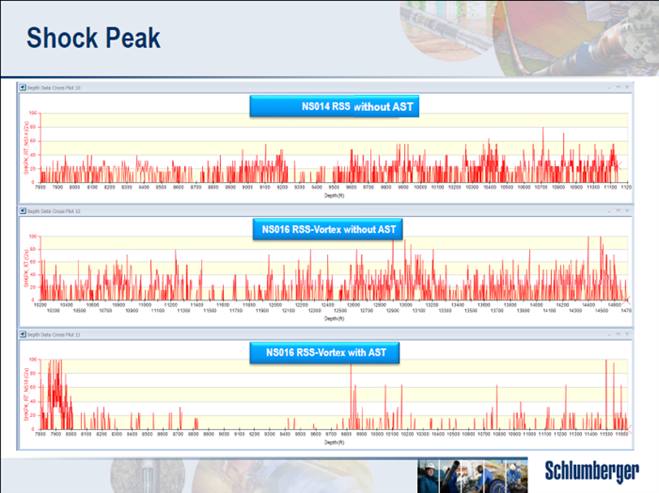

Although friction effects are difficult to remove in deep wells, Zadco figured the AST would be good for limiting the string effect from affecting the rock-cutter interface. The DD contractor was given the task of documenting the effect from downhole data:

Results

The MWD shocks came down to harmless levels. The operational efficiency improved significantly. Since then, more than 50 wells (2019) have been drilled, some deeper than 40,000′. (12,000m)