Objectives

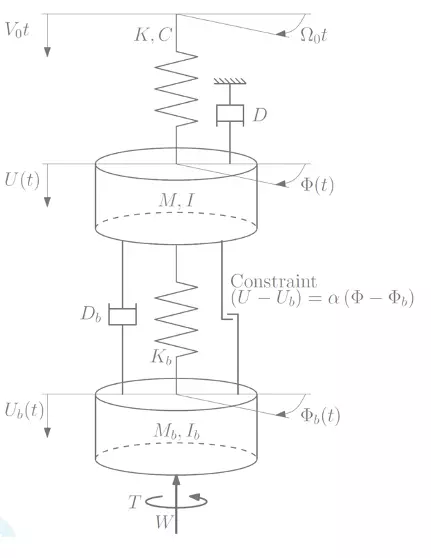

The primary objective was to maximise drilling efficiency in the 5 5/8” section through the hard abrasive Lower Fulmar Sandstone. A turbine BHA was initially chosen to meet this arduous challenge however Total had concerns due to twist offs and poor bit performance on previous wells and the use of a Turbine could indeed exacerbate these issues. With this in mind, Total decided that the least risky strategy would be to run an AST on a rotary BHA.

FACTS

Tool

4 ¾” XDT-AST (Rated to 220 deg. C)

Country

UK

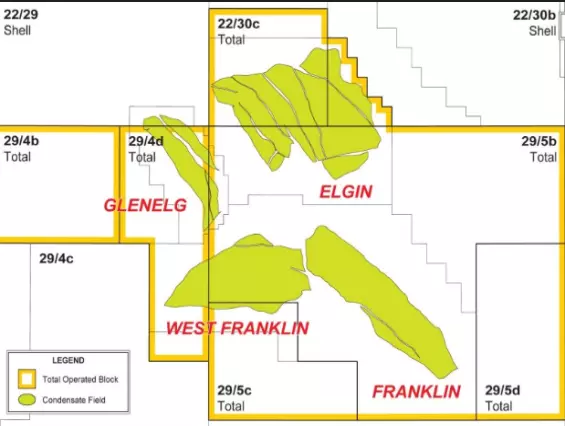

Field

Franklin West

Rig

Rowan Gorilla V

Well

29/5b-H2z

Operator

Total E&P UK

Bit

5 5/8”

BHA

5 5/8” PDC, NB Stab, Float Sub, Stab, DC,Tomax AST

May 2015

Results

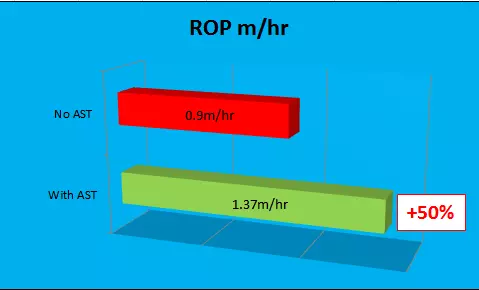

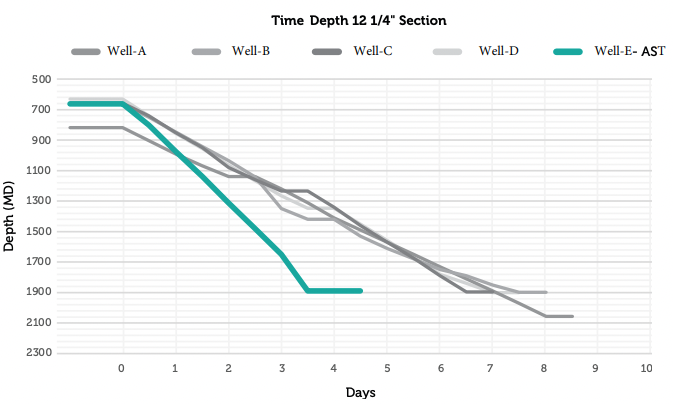

A 4 ¾” Tomax AST, with high temperature seals on a rotary assembly proved to be the correct choice for Total with the tool providing the longest bit run in the Lower Fulmar formations to date only tripping due to hours on the BHA components. Bit cutting structures were graded 2-2 and 2-1 compared to offsets of 3-3 and 3-4. No twist offs or torque issues were experienced and the expected ROP for the section was increased by 50%.

Value

With a spread rate in excess of £300,000/day, the Tomax AST provided a saving in excess of £2.2 Million for ROP alone – before counting the saving from no failures.