A production packer was set in the wrong place and needed milling out from inside a new, high grade tubing. In order to safely mill the packer with minimal risk to the tubing, an AST was used.

Objectives

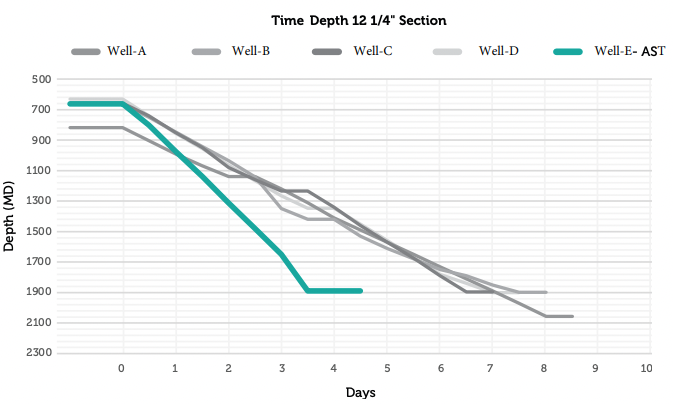

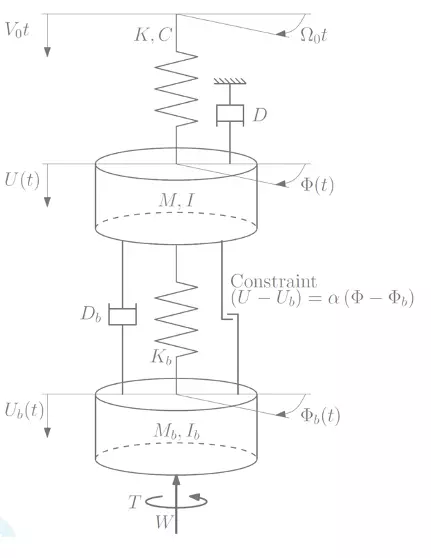

A production packer with a 1m (3’) tubing stick-up was prematurely set at 5,500m (18,000’) and an 84 degree deviation in a Statfjord well. The packer needed to be safely and precisely removed before completion of the well could continue. Based on run data from casing-milling with an Anti Stick-slip Tool (AST), the StatoilHydro team decided to use an AST along with a Baker Packer Mill to maximize efficiency while at the same time keep milling parameters under control.

FACTS

Tool

6 ¾” XD-AST

Client

StatoilHydro

Country

Norway

Rig

Statfjord C

Section

Packer Mill

Results

A 6 ¾” XD-AST tool was placed between the Packer Mill and a full gauge Melon Mill. After tagging the fish, stable parameters were quickly established and milling progressed steadily down the tubing stump and continued until the packer was free. The catcher extension brought to surface the upper part of the packer and a jetting run was made to ensure no swarf was in the way before the bottom section was retrieved.

Value

Completion of the well could continue according to plan.