All reports

-

Milling damaged pipe on coiled tubing

Milling collapsed pipe is difficult and in this case it was done deep down in an…

-

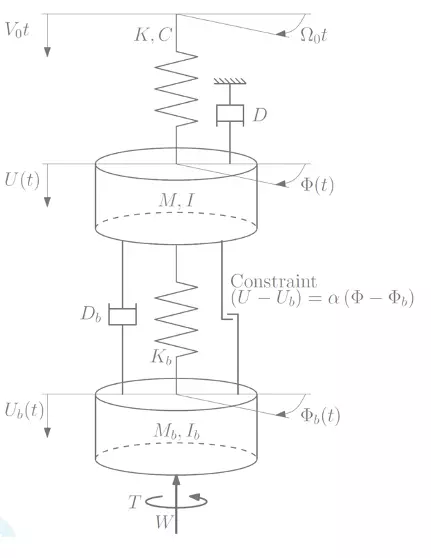

Reducing surface drilling torque in ERD well

The maximum drilling torque supplied from the Top Drive is defined by the highest peaks produced…

-

Milling Production Packer on drill-pipe

A production packer was set in the wrong place and needed milling out from inside a…

-

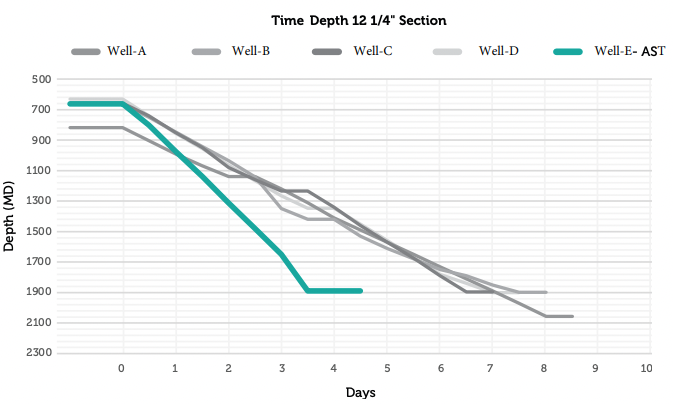

Using AST for directional drilling with rig heave

Bad weather on floating drilling facilities can make the heave compensator struggle and the WOB becomes…

-

Drilling difficult sediments and hard chalk, offshore UK

Offeset data stated a minimum of two bit run was needed to reach TD in a…

-

Drilling with slim motor BHA from floating rig

Drilling a slim hole from a semi-submersible in rough seas was almost impossible due to inadequate…

-

Drilling three geological periods in one drill-bit run

Use of very aggressive PDC cutters, a RSS system with a mud motor and an AST…

-

Drilling long HTHP multi-lateral wells

The AST principle provides a stabilized load on the bit in lateral and extended reach wells…

-

Vibration challenges in top-hole drilling

Severe drilling vibrations in top-hole section created unacceptable noise and risk. An AST was implemented to…

-

Under-reaming a difficult, fractured formation

A troublesome formation known to lock-up the cutters and cause twist-offs was to be drilled with…