Milling collapsed pipe is difficult and in this case it was done deep down in an extended reach well. To be able to land and engage the mill, two AST tools were run in tandem.

Objectives

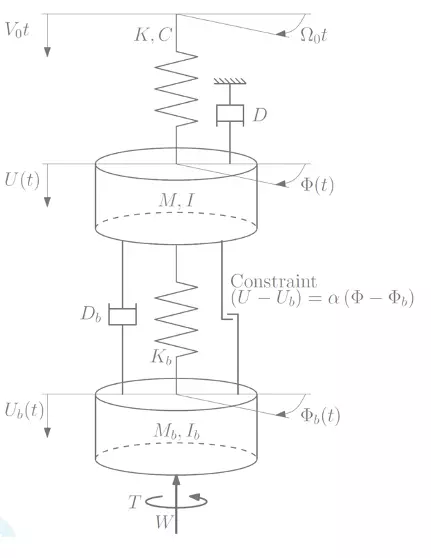

A mechanical restriction, likely a tubing deformation, was holding back access for scale removal through the perforated interval in well A-31 on the Talisman-operated Gyda field. Based on previous experience of Anti Stick-slip Tool (AST) technology, the Coiled Tubing contractor suggested a tandem AST configuration to optimize the chances of engaging the deformation without stalling the mill.

FACTS

Tool

2 7/8” TT-AST

Client

Talisman

Country

Norway

Rig

Gyda Platform

Coil OD

2 7/8”

Results

A lower BHA consisting of two 2 7/8” TT-AST tools and a Baker 2 7/8” X-treme motor with 3.39” OD Turbo Mill was run. The mill tagged without stalling and milling progressed steadily except for one stall encountered due to a feed problem from surface. The restriction was cleared in three hours allowing access for milling scale through the perforated interval from 6,570m (21,550’) MD.

Value

The total service scope for the well required 12 round-trips. With no stalls during milling, there were no significant hot-spots produced and the full scope was completed with one coil saving about USD 1 mill.