The campaign needed extensive under-reaming and caused concerns over vibrations and long bit trips.

Objective

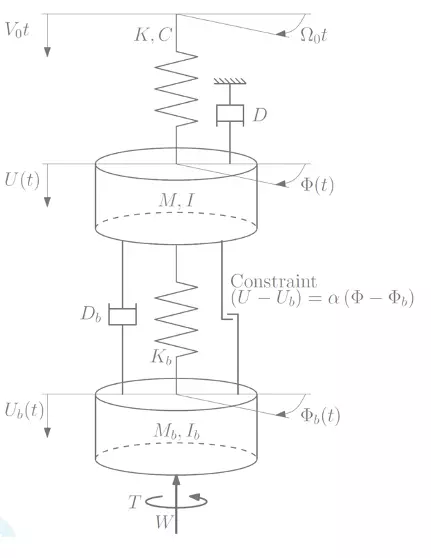

The group of partnering operators went diligently through all available methods for vibration mitigation when planning a deep exploration project in the Nile Delta. Real-time dynamics, shock recorders and absorbers were all brought in for evaluation. This evaluation also included the Tomax XC-AST.

FACTS

Tool

9 ½, 8 ¼ and 6 3/4” XC-AST

Client

Total

Country

Egypt

Rig

EDC 56

Section

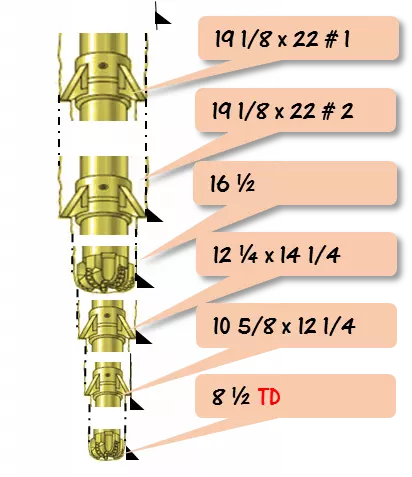

19 1/8 x 22,16½, 12 ¼ x 14¼,10 5/8 x12¼ and 8 1/2”

BHA

Pendulum first and last section. Else RSS. All PDC. UR in three of the sections (left)

July 2017

Results

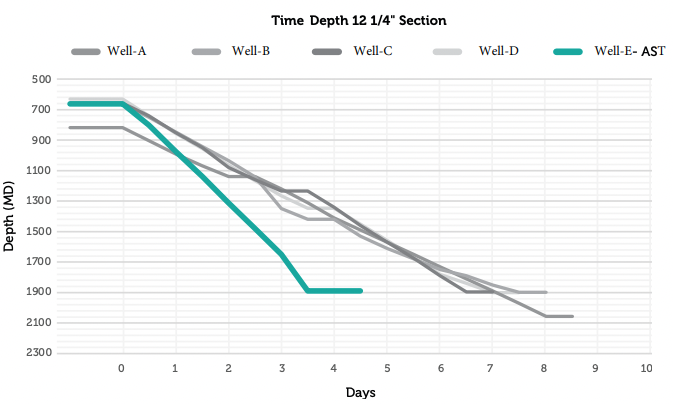

The Tomax tool was tested by overlap in a particularly challenging section. Based on the test results, Total put the bet on Tomax and ordered tools to the well site for five consecutive sections. One dimension was left for contingency. Three of the sections included under-reamer:

Value

At TD, an impressive record of efficiency was revealed: The Total team had drilled four of the five sections in one bit run. Only the longest section needed an extra bit. Total had proven it was possible to mitigate the risk from vibration through a large variety of sediments.