A troublesome formation known to lock-up the cutters and cause twist-offs was to be drilled with under-reamer. An AST was deployed to solve the problem.

A particular package of Oligocene sediments under the Snorre A TLP caused trips and delays when drilling the 16” section from the rig. Then the need for ECD management required the interval to be under-reamed up to 17 ½” while drilling;

FACTS

Tool

9 1/2” XD-AST

Client

Statoil

Country

Norway

Field

Snorre

Rig

Snorre A

Section

16” x 17 ½”

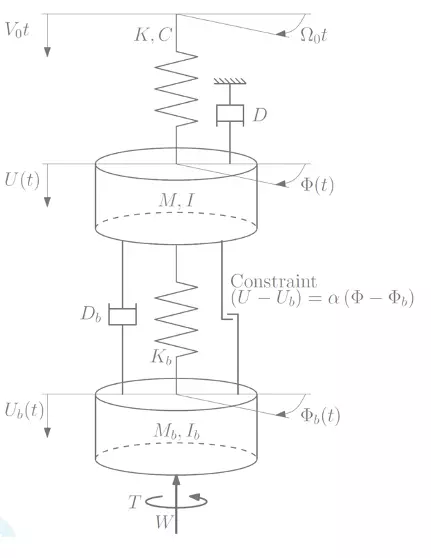

BHA

16” bit, PowerDrive RSS, MWD, 17 ½” XR-Reamer, AST, DC, jars and 5 ½” DP

Objectives

The established strategy for drilling the section was based on avoiding twist-off with a switch to roller-cone type bits when strong torsional vibrations occurred. Now with a PDC reamer, this strategy had to be abandoned and with input from Security DBS, Statoil changed to Anti Stick-slip Tool (AST) technology to mitigate risks.

Results

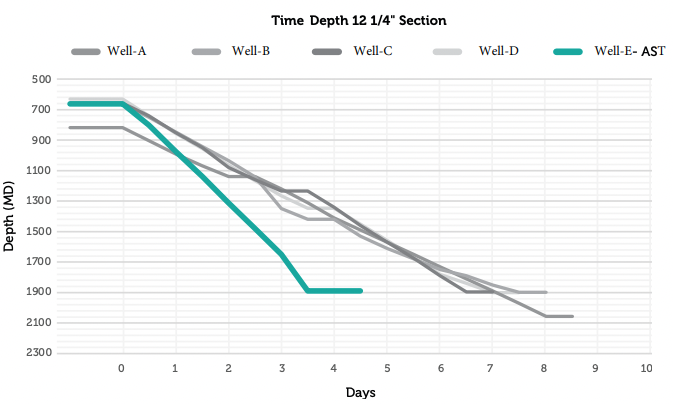

The new BHA with AST and under-reamer drilled to section TD in one run using half the time of previous sections. Torsional vibrations were not an issue and the results were safely repeatable.

Value

The direct saving was around USD 1 million per well and the achievement was nominated the most significant process improvement for Snorre A in that year.