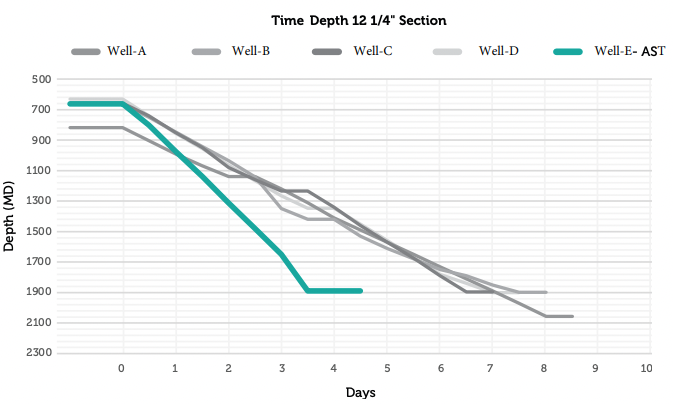

Severe drilling vibrations in top-hole section created unacceptable noise and risk. An AST was implemented to solve the problem.

Objectives

Severe surface vibrations and noise were significant operational and environmental concerns when drilling conglomerates and marl in the 17 ½” top hole section with a roller cone bit in the Austrian part of the Molasse Basin. To improve on the situation the major operator in the area, RAG decided to run an Anti Stick-slip Tool. The BHA was not changed from previous wells other than including the AST. This gave a good basis for pinpointing the effect from the tool.

FACTS

Tool

9 1/2” XD-AST 9” HB-AST

Client

RAG

Country

Austria

Rig

RAG E200

Section

17 ½”

BHA

Rock-bit and packed rotary BHA

Results

The AST tools were run in multiple wells with the same good results; the vibrations were significantly reduced and the ROP increased compared to offset wells;

Value

By reducing surface vibrations, the noise level was reduced to a level that is acceptable when drilling in a residential area and damage to surface equipment was eliminated. Furthermore, drilling time was reduced and the sections were drilled without tripping.