All reports

-

Double ROP and Footage with PDMin Southeast Turkey

Çalık Petrol had been struggling with low drilling efficiency, toolface control and bit wear in Southeast…

-

Double Efficiency in Carbonate Laterals

Drillers often praise the AST for making their job easy long before the engineers have calculated…

-

Bright Future for Deep Drilling

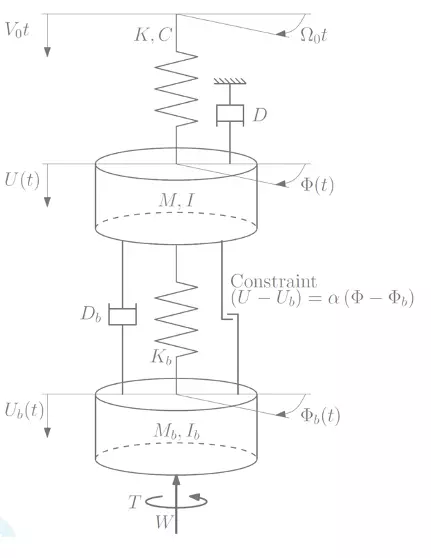

Objective The PDC cutters rely on an accurate force-feed to deliver their unique capacity for efficiency…

-

Improvements in different formations

Midland Basin (Spraberry and Wolfcamp) Objective The Tomax Anti Stick-Slip Tool (AST) reduces motor wear from…

-

Improved Performance With PDM

Southern Midland Basin Objective The Tomax Anti Stick-Slip Tool (AST) reduces motor wear from stalls. That…

-

US Operator Presents AST Performance

Normally it is Tomax that makes presentations about field statistics and performance to operators. This time…

-

Qualification for Giant ERD Oilfield

Zadco UAE (Upper Zakum Development Company), with majority shareholder ADNOC, needed to expand ERD capabilities beyond…

-

Ivar Aasen

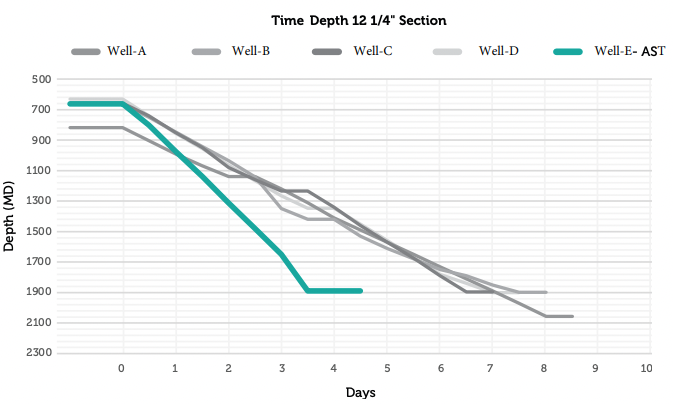

First case report with practically full AST implementation The Aker BP drilling team had an ambitious…

-

Drilling basement rock

New, counterforce assisted XC-AST Reveal Hard Rock Potential with PDC Bits Objective The cost of hard…

-

Proving a New Hypothesis

Drilling hard carbonates is often a costly affair with slow ROP and equipment damage. At the…