Drilling, shale, play, unconventional, lateral, Permian, Eagle Ford

The drilling of long laterals for unconventional resources which is typical in shale plays, is on the rise. Tomax is providing technology which enables faster drilling speeds in such operations in several areas. Here are some field results which demonstrate the core value of applying the Anti Stick-Slip Tool (AST) technology for drilling in unconventional shale beds.

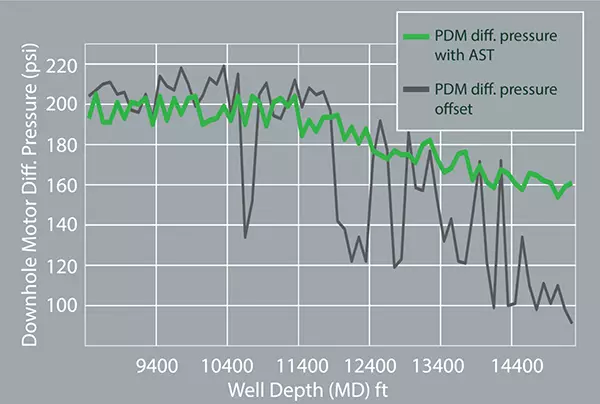

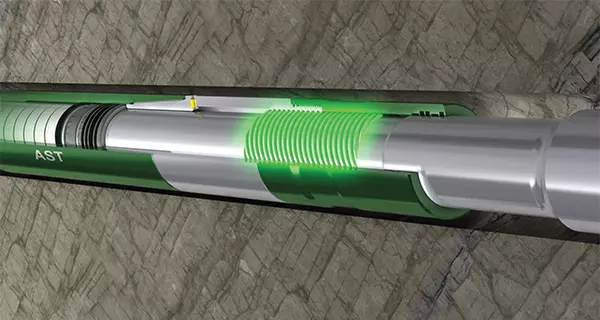

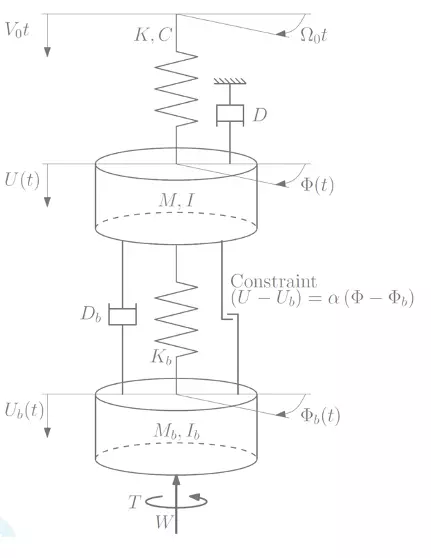

The use of the AST for drilling shale bed laterals provides two main benefits: it expands the operational window of the drill bit to allow for a faster ROP without initiating severe vibrations, and it provides for a steadier load when friction makes the WOB feed erratic. Figure 1 (under more images) shows the internal part of the AST providing the steady torsional loading, while Figure 2 shows the mud motor differential pressure demonstrating the difference when the AST is included to stabilize the load in a Permian Basin lateral.

FACTS

Tool

6 ¾” XD-AST

Country

Australia and USA

Field

Cooper Basin and Eagle Ford

Section

8½” Lateral

BHA

Bit – RSS – MWD – AST

Results I

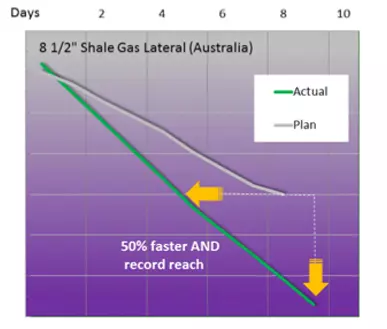

Figure 3 shows a marked AST effect in a Shale Gas project in the Cooper Field, central Australia. The operator utilized the AST to extend the laterals as far as possible. The result was not only a record extension but also a significant, 50% faster rate of penetration from where the AST was included in the BHA.

Results II

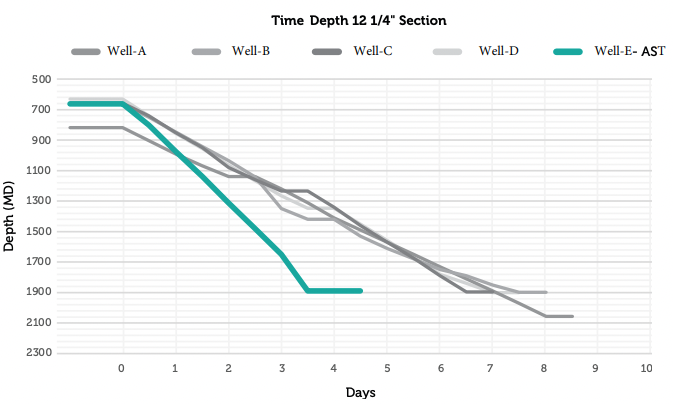

To enter the US unconventional market, the AST has been run in several test wells to verify its ability to deal with torsional vibrations and increase the drilling speed. Now a 20-30% faster ROP is commonly observed in already optimized drilling operations. The expanded window for drilling parameters is also used to extend the unconventional laterals to increase well productivity. Figure 4 shows a performance example from drilling in the Eagle Ford area.

Value

The 20-50% faster ROP provided by the Anti Stick-Slip Tool in these unconventional wells is reducing well costs. In addition to the direct savings is the potential productivity contribution from well extensions. Tomax is also observing that savings have been increasing to a point where the operators have refined the use of the technology in combination with more aggressive drill bits to attain their cost-cutting goals through faster drilling.