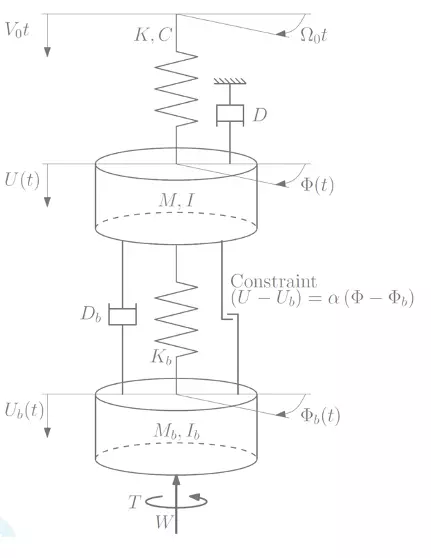

Torque arrestors and other features are added to reduce vibrations and to keep PDC drill bits safe. ROP however suffers. The AST allows for the fast, aggressive bits to be used again.

Objectives

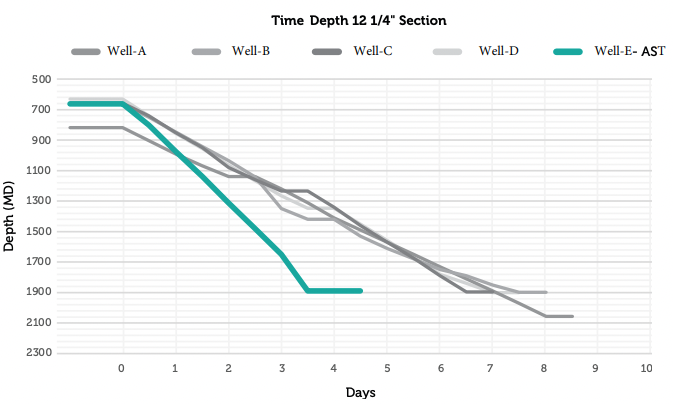

The 12¼” section was planned to be a 2,467ft long section building from vertical to 25° through the Haisborough, Bunter sst, Bunter Shale and top Zechstein formations. Section objectives were to drill to TD in one bit run, maintain directional control and optimise ROP. Based on offset data, an average ROP of around 20ft/hr was expected.

FACTS

Well

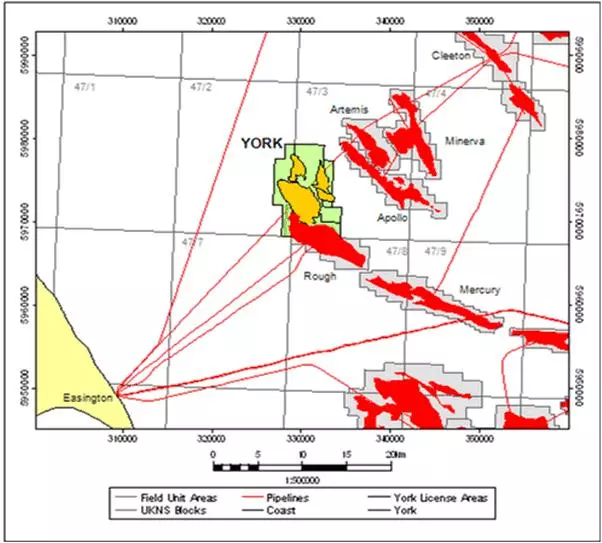

York 47/03a-Y2z

Country

UK

Rig

NJR

Section

12 ¼”

BHA

12¼” RSH619M PDC, Weatherford RSS, MWD, NMFS, Tomax AST…

Results

The section length of 2,389ft was drilled in one bit run with an average ROP of 39ft/hr – an ROP increase of 100% compared to the direct offset well. The Tomax AST allowed a more aggressive, modified bit to be run which involved removing the ROP/depth of cut limiters on the bit. The Tomax tool acts like a constantly varying depth of cut limiter preventing cutter over-engagement and the resulting high torque levels, stick slip and damaging vibrations. No vibrations were recorded and directional control was excellent. The bit was POOH in excellent condition (0,1) and was suitable for re-running.

Value

The 12¼” section was drilled 2.5 days ahead of plan, saving an estimated £600,000 on drilling hours alone.